- Home

- Brand

- Model Number

- Motor Power

- Pressure

- Ultimate Vacuum

- 0.2 Pa (8)

- 0.2 Pa (15 Micron) (9)

- 0.2pa; 15 Microns (3)

- 0.3 Pa (3)

- 0.3 Pa, 25 Microns (33)

- 0.3pa (10-6 Bar) (3)

- 0.3pa / 2.5 Microns (11)

- 0.3pa(2*10ˉ¹pa (17)

- 1.5 Microns (0.2 Pa) (6)

- 2pa (48)

- 3*10-1pa (6)

- 37.5 Microns (5 Pa) (5)

- 3x10-1pa, (15)

- 40 Microns (10)

- 5 Pa (49)

- 5 Pa 0.05mbar (4)

- 5pa (54)

- 5pa / 0.05mbar (61)

- 5pa 0.05mbar (30)

- 5pa-0.05mbar (32)

- Other (2400)

- Voltage

Maple Tree / Sap Extraction Vacuum Pump 3.8cfm@20psi 26.6hg +Moisture Trap 115v

BRAND NEW DIY Pond Aeration's 3/4 HP- HIGH CFM Low PSI Rocking PISTON Vacuum Pump Ready to hard wire into a junction box, attach a plug to, or splice onto a cord. Easily performed by household tools. Search online for lots of how to videos and guides.

These can typically hand runs of 100-200 TAPS! The Piston technology provides a long life, high performance piston compressor with capabilities of air flows up to 4.94 cfm at pressures up to 44 P. These come complete with an air filter, capacitor, and fan guards! We have complete service kits available for this model that is field serviceable in our store as well!

This item is also available in 220V if needed - just ask! Picture is for representation only - actual item may vary in shape, style, color, etc.

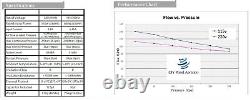

OPEN FLOW 140lpm(4.94cfm) Max Pressure Cont. MAX Vacuum -900mbar (26.6HG). MAX Pressure Intermittent 3 bar 44 PSI. Current at rated load 5.45A Power at rated load 600W(0.80HP) Motor Type PSC Voltage/Frequency 115V/60Hz. Starting Current 19A Net Weight 7.5kg(16.5lbs). This listing also comes with 1 - Heavy Duty Vacuum Trap w / Gauge, hardware, adjustable valve (Regulator), and 3/8" hose barb outlet, 1/4" MNPT inlet fitting. The pump does not have a shut-off valve. The moisture trap is a backup measure in case the capture vessel is overfilled, but it does not have an internal valve as. It would be too restrictive for these powerful pumps. In short, the operator needs to monitor the filtration on a regular basis. The compressor will need to be mounted away from any source of water - they CANNOT get wet at all. WE have brand new locking metal cabinets in our store or build your own. If mounted in an enclosure they MUST have a cooling fan blowing on them. Typical Maple Setup and Guidelines. How does vacuum pressure affect the run? Below are a few examples of Tree Pressures and sap flow. 10-17 psi = decent sap run. 18-24 psi = Better sap run. 25+ psi = Ideal sap run. 15 of Hg of vacuum = 5 psi change in pressure.20 of Hg of vacuum = 10 psi change in pressure. Vacuum systems turn a decent sap run into a great sap run and can increase yield by 60 to 100%. A vacuum system must be capable of producing a vacuum of 15 of mercury at the far end of the lateral. Tubing for it to be considered economical. A vacuum pump's capacity is measured by how much air it can move in a certain amount of time - cubic.

For every 100 taps in tubing system, a pump with 1 to 1 ½ CFM is needed. If 500 taps are on vacuum, You would typically need a pump with a capacity of 5 to 7+ CFM. WE have pumps available up to 9+ CFM. Most use 5/16 Lines - keep lines steep, tight and as straight as possible. NOT Included - Listing is for the PUMP and Trap ONLY. With vacuum - 1 to 8 taps per lateral line. W/O vacuum - 11 to 16 taps per lateral line. When you are designing a Tubing System - the goal is to get vacuum at the tap hole. Long spans of tubing will cover a lot of. Area but will have a lower vacuum. Short spans will cover less area but will increase your vacuum in the line. 90 to 160 feet apart (up to 260 feet apart without vacuum) and less than 1000 feet variation will occur.160' x -900' will cover 3.5 acres. Vacuum system mainlines should maintain a constant slope of 1-1/2 to 3+%.

A well thought out vacuum tube setup would have the following. Maximum vacuum at the tap hole. Faster tapping and cleaning tubing. Tap only trees 11 inches diameter at chest height and larger. 1 tap hole in trees 11 to 18 inche.

2 tap holes in trees greater than 18 inches. Place no more than 2 tap holes per tree. The more holes, broken branches, scars, etc. Can build up in the tree. Drill tap holes at a slight upward angle to prevent sap pooling. Drill "check-valve" spouts at a flat angle. Use the smaller-diameter "health spouts" (1/2- or 3/4-inch spouts). Drive spouts with care to avoid splitting the bark and wood. 3/4 inch spouts should be no more than 2 1/2 inches deep and for the smaller. Spouts, no more than 1 1/2 inches deep.Remove spouts from tap holes immediately after the season. A good sap run will yield about 1 gallon of sap per tap. 750 taps x 1 gal/tap = 750 gallons.

Reference / Credit - University of NH.